Video

Product Display

AUTOMATIC FILLING CAPPING LABELING LINE

>Suitabel for all kinds of liquidsauce paste and filling and capping and labeling.

>Filling with piston feeding pumpwhich is convenience to feeding materail.

>Capping machine has two capping headwith high production speed.

This automatic piston pump filling machine is equipped with feeding pump,this is more convenient for feeding filling

material.Different filling range can be chosen and multiple filling nozzle can be customized according to operation need.

It is widely used in the filling of various semi-fluids, pastes, viscous bodies, sauces and various granule-containing material, such as pulp-containing beverages,shampoo, laundry detergent, hand washing, honey, jams, ketchup, chili sauce, bean paste, shrimp paste, apple sauce, salad dressing.

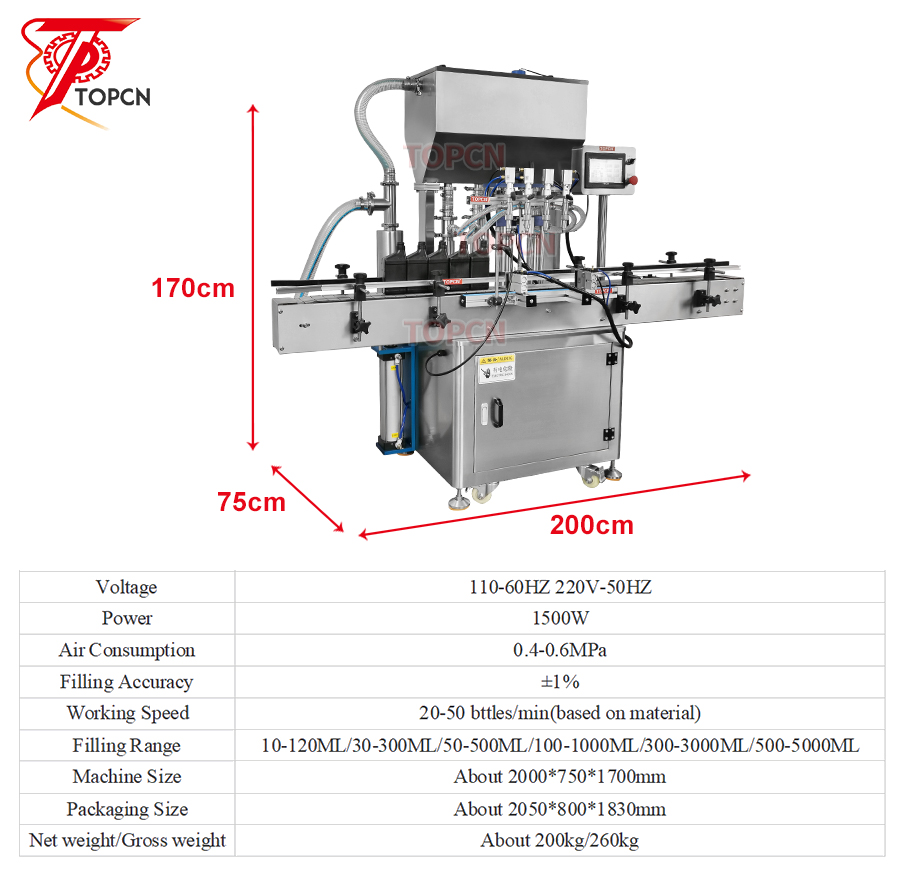

Automatic Filling Machine | |

Voltage | 110-60HZ 220V-50HZ |

Power | 1500W |

Air Consumption | 0.4-0.6MPa |

Filling Accuracy | ±1% |

Working Speed | 20-50 bttles/min(based on material) |

Size Of Filing Nozzle | φ10mm |

Size Of Air Compressor Connector | Φ8mm |

Filling Range | 10-120ML/30-300ML/50-500ML/100-1000ML/300-3000ML/500-5000ML |

Machine Size | About 2000*750*1700mm |

Packaging Size | About 2050*800*1830mm |

Net weight/Gross weight | About 200kg/260kg |

Automatic Capping Machine | |

Working voltage | AC220V/110V 50- 60HZ |

Capping head | 2 |

Bottle height | 100-380mm |

Cap Diameter | 18-70mm |

Bottle Diameter | 20-160mm |

Working speed | 30-60 bottles / minute (depending on bottle and cap size) |

Working pressure | 0.4-0.6MPa |

Machine size | About 200*70*188mm |

Machine weight | About 252kg |

Package Size | About 205*74*203cm |

Gross weight | About 284kg |

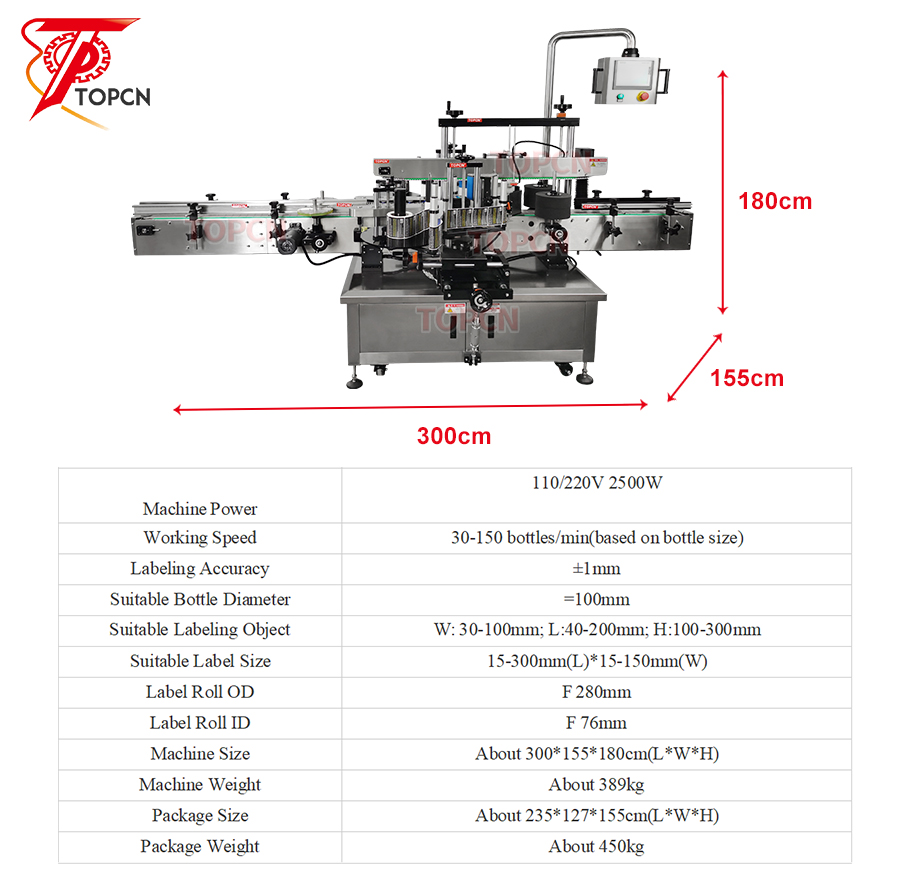

Automatic Double Sided Labeling Machine | |

Machine Power | 110/220V 2500W |

Working Speed | 30-150 bottles/min(based on bottle size) |

Labeling Accuracy | ±1mm |

Suitable Bottle Diameter | ≤100mm |

Suitable Labeling Object | W: 30-100mm; L:40-200mm; H:100-300mm |

Suitable Label Size | 15-300mm(L)*15-150mm(W) |

Label Roll OD | Φ280mm |

Label Roll ID | Φ76mm |

Machine Size | About 300*1550*180cm(L*W*H) |

Machine Weight | About 389kg |

Package Size | About 235*127*155cm(L*W*H) |

Package Weight | About 450kg |

Product Details

Anti-dripping piston filling nozzles

Ensure material don’t dripped out during filling. And the the height of filling nozzles can be

adjusted according to bottle size.

Feeding Pump

Equipped with piston feeding pump,it can feed filling material automatically and no need to pour material into tank.This helps to save production labor and improve production efficiency.

Liquid level device and feeding pump

Machine with liquid level sensor in hopper, when the sensor detect material below the level, piston feeding pump will feed filling material automatically and no need to pour material into tank.

2 capping heads

2 station high quality capping head,it is suitable for close the bottle with two caps, also machine with two vibratory to arrange

bottle caps before capping work.This device should be customized according to bottle caps size.

Labeling Machine

This machine is not only suitable for flat bottles,it is also suitable for round

bottles.It can realize single side or double side labeling by replacing the round bottle labeling structure.

Double sides labeling machine is made of high quality components,ensure the label can be kept flat and winding smooth during working,